-

Star flexible coupling

-

Plum-shaped elastic coupling

-

Slider coupling

-

Diaphragm coupling

-

Elastic sleeve pin coupling

-

Elastic pin coupling

-

Elastic pin gear coupling

-

Drum gear coupling

-

Rigid coupling

-

Tyre coupling

-

Universal coupling

-

Water pump coupling

-

Roller chain coupling

-

Reducer bracket

-

Blender

-

Stuffing box

-

Expansion sleeve

-

Various coupling accessories

-

Product Navigation

- LM type basic plum blossom elastic coupling

- LT type (formerly TL type) elastic sleeve pin coupling

- LMD (formerly MLZ) type single flange plum-shaped bullet

- XL type star elastic coupling

- Ever-Power Factory Slider Coupling

- Ever-Power explains the elastic pin teeth for you

- Operation and structure of star coupling

- The editor will introduce you to each model

- The coupling is divided into lubricated and non-lubricated

- What to consider when buying a coupling

-

更新 更新

-

Product display Coupling > Product center > Rigid coupling >

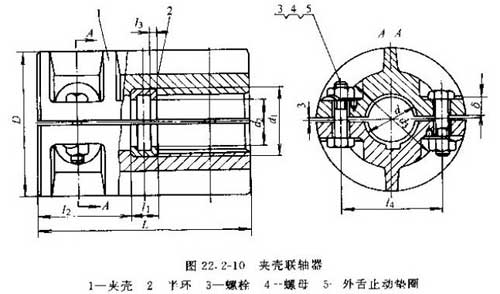

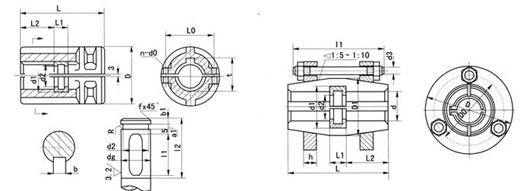

Detailed parameters of JQ type-jacket coupling

During assembly and disassembly of the JQ type clamp coupling, the shaft does not need to move axially, so the assembly and disassembly are very convenient. The disadvantage of the clamp coupling is the low accuracy of the axis of the two shafts, the structure and shape are more complicated, and the manufacturing and balance accuracy Low, only suitable for low speed and stable load occasions, usually the maximum outer edge linear velocity is not more than 5m/s, when the linear velocity exceeds 5m/s, balance verification is required.

In order to improve the balance, the bolts should be installed between the forward and reverse phases.Jacketed couplings do not have axial, radial and angular compensation performance.

The main features of JQ type clamp coupling are as follows:

(1) Light weight, ultra-low inertia and high sensitivity;

(2) Maintenance-free, super oil and corrosion resistance;

(3) Eccentricity cannot be tolerated, and the shaft should be exposed as much as possible during use;

(4) The main body material can be cast steel/stainless steel;

(5) The fixing method includes clamping and top wire fixing;

(6) Simple structure, convenient for loading and unloading;

The characteristics of the vertical clamp coupling are similar to those of the clamp coupling, simple structure, convenient assembly and disassembly, suitable for low-speed (maximum circumferential speed of 5m/s), no impact, and stable vibration load occasions. For the connection of vertical shafts such as agitator.

| Calibration symbol | Aperture | Mmax | D | L |

L1 (H8/j7) |

L2 | L0 | n-d0 |

d1 (H11/h11) |

d2 (H11) |

a1 (H11) |

b1 | l1 | l2 | R | f | b | t | Weight(kg) |

| JQ-25 | 25 | 90 | 95 | 110 | 20 | 45 | 58 | 4-12 | 32 | 20 | 5 | 4 | 35 | 60 | 0.2 | 0.4 | 8 | 28.3 | 4.47 |

| JQ-30 | 30 | 90 | 102 | 130 | 20 | 55 | 64 | 4-14 | 38 | 25 | 5 | 4 | 45 | 70 | 0.2 | 0.4 | 8 | 33.3 | 4.47 |

| JQ-35 | 35 | 236 | 118 | 162 | 20 | 71 | 80 | 6-14 | 43 | 30 | 5 | 4 | 55 | 85 | 0.4 | 0.6 | 10 | 38.3 | 7.60 |

| JQ-40 | 40 | 236 | 118 | 162 | 20 | 71 | 80 | 6-14 | 48 | 35 | 5 | 6 | 55 | 85 | 0.4 | 0.6 | 12 | 43.3 | 7.60 |

| JQ-45 | 45 | 530 | 135 | 190 | 24 | 83 | 94 | 6-14 | 57 | 37 | 6 | 5 | 70 | 100 | 0.4 | 0.6 | 14 | 48.8 | 10.85 |

| JQ-50 | 50 | 530 | 135 | 190 | 24 | 83 | 94 | 6-14 | 62 | 42 | 6 | 5 | 70 | 100 | 0.4 | 0.6 | 14 | 53.8 | 10.85 |

| JQ-55 | 55 | 530 | 135 | 190 | 24 | 83 | 94 | 6-14 | 67 | 47 | 6 | 5 | 70 | 100 | 0.6 | 1 | 16 | 59.3 | 10.85 |

| JQ-60 | 60 | 1400 | 172 | 250 | 30 | 110 | 124 | 8-18 | 73 | 50 | 8 | 6 | 100 | 130 | 0.6 | 1 | 18 | 64.4 | 25.06 |

| JQ-65 | 65 | 1400 | 172 | 250 | 30 | 110 | 124 | 8-18 | 78 | 55 | 8 | 6 | 100 | 130 | 0.6 | 1 | 18 | 69.4 | 25.06 |

| JQ-70 | 70 | 1400 | 172 | 250 | 30 | 110 | 124 | 8-18 | 83 | 60 | 8 | 6 | 100 | 130 | 0.6 | 1 | 20 | 74.9 | 25.06 |

| JQ-80 | 80 | 2650 | 185 | 280 | 38 | 131 | 138 | 8-18 | 94 | 7 | 10 | 8 | 110 | 145 | 0.6 | 1 | 22 | 85.4 | 30.16 |

| JQ-85 | 85 | 2650 | 185 | 280 | 38 | 121 | 138 | 8-18 | 99 | 75 | 10 | 8 | 110 | 145 | 0.6 | 1 | 22 | 90.4 | 30.16 |

| JQ-90 | 90 | 5200 | 230 | 330 | 38 | 146 | 164 | 8-23 | 105 | 80 | 10 | 8 | 140 | 170 | 0.6 | 1 | 25 | 95.4 | 56.38 |

| JQ-95 | 95 | 5200 | 230 | 330 | 38 | 146 | 164 | 8-23 | 110 | 85 | 10 | 8 | 140 | 170 | 0.6 | 1 | 25 | 100.4 | 56.38 |

| JQ-100 | 100 | 5200 | 230 | 330 | 38 | 146 | 164 | 8-23 | 115 | 90 | 10 | 8 | 140 | 170 | 0.6 | 1 | 28 | 106.4 | 56.38 |

| JQ-105 | 105 | 5200 | 230 | 330 | 38 | 146 | 164 | 8-23 | 120 | 95 | 10 | 8 | 140 | 170 | 0.6 | 1 | 28 | 111.4 | 56.38 |

| JQ-110 | 110 | 9000 | 260 | 390 | 46 | 172 | 190 | 8-23 | 125 | 100 | 12 | 10 | 160 | 200 | 0.6 | 1 | 28 | 116.4 | 90 |

| JQ-115 | 115 | 9000 | 260 | 390 | 46 | 172 | 190 | 8-23 | 130 | 105 | 12 | 10 | 160 | 200 | 0.6 | 1 | 32 | 122.4 | 90 |

| JQ-120 | 120 | 9000 | 260 | 390 | 46 | 172 | 190 | 8-23 | 135 | 110 | 12 | 10 | 160 | 200 | 0.6 | 1 | 32 | 127.4 | 90 |

| JQ-125 | 125 | 15000 | 280 | 440 | 54 | 193 | 210 | 10-23 | 140 | 115 | 14 | 12 | 180 | 225 | 0.6 | 1 | 32 | 132.4 | 125 |

| JQ-130 |

130 |

15000 | 280 | 440 | 54 | 193 | 210 | 10-23 | 146 | 118 | 14 | 12 | 180 | 225 | 0.6 | 1 | 32 | 137.4 | 125 |

| JQ-140 | 140 | 15000 | 300 | 440 | 54 | 193 | 230 | 10-23 | 158 | 128 | 14 | 12 | 180 | 225 | 0.6 | 1 | 36 | 148.4 | 125 |

| JQ-150 | 150 | 28000 | 340 | 500 | 64 | 218 | 260 | 10-33 | 170 | 134 | 16 | 14 | 200 | 255 | 0.6 | 1 | 36 | 158.4 | 215 |

| JQ-160 | 160 | 28000 | 340 | 500 | 64 | 218 | 260 | 10-33 | 180 | 144 | 16 | 14 | 200 | 255 | 0.6 | 1 | 40 | 169.4 | 215 |

| JQ-180 | 180 | 31000 | 380 | 560 | 72 | 244 | 300 | 10-33 | 200 | 162 | 18 | 16 | 240 | 285 | 1 | 1.5 | 45 | 190.4 | 350 |

| JQ-200 | 200 | 33750 | 420 | 640 | 80 | 280 | 340 | 10-33 | 220 | 182 | 20 | 18 | 270 | 325 | 1 | 1.5 | 45 | 210.4 | 516 |

Note: JQW type is a clamp shell coupling is a JQ clamp shell coupling with a message suspension ring to avoid repeated axial positioning. It can be used in a single pivot frame.

You may be right | Flange coupling | GYD type flange coupling | Interested in other products

- LM type basic plum blossom elastic coupling LT type (formerly TL type) elastic sleeve pin coupling LMD (formerly MLZ) type single flange plum-shaped bullet XL type star elastic coupling T type plum blossom hexagonal water pump counter wheel pad

-

Popular products

- JQ type-jacket coupling Flange coupling GYD type (formerly YLD type) has a centering tenon flange

-

Related Products

-

related news