-

Star flexible coupling

-

Plum-shaped elastic coupling

-

Slider coupling

-

Diaphragm coupling

-

Elastic sleeve pin coupling

-

Elastic pin coupling

-

Elastic pin gear coupling

-

Drum gear coupling

-

Rigid coupling

-

Tyre coupling

-

Universal coupling

-

Water pump coupling

-

Roller chain coupling

-

Reducer bracket

-

Blender

-

Stuffing box

-

Expansion sleeve

-

Various coupling accessories

-

Product Navigation

- LM type basic plum blossom elastic coupling

- LT type (formerly TL type) elastic sleeve pin coupling

- LMD (formerly MLZ) type single flange plum-shaped bullet

- XL type star elastic coupling

- Ever-Power Factory Slider Coupling

- Ever-Power explains the elastic pin teeth for you

- Operation and structure of star coupling

- The editor will introduce you to each model

- The coupling is divided into lubricated and non-lubricated

- What to consider when buying a coupling

-

更新 更新

-

Product display Coupling > Product center > Elastic pin gear coupling >

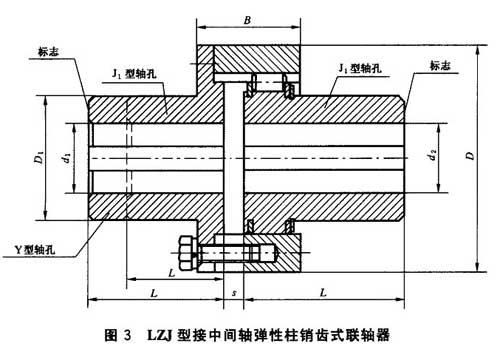

LZJ (formerly ZLZ) type connecting intermediate shaft elastic pin gear coupling

LZJ (formerly ZLZ) type intermediate shaft elastic pin gear coupling has a large transmission torque. At the same torque, the rotation diameter is mostly smaller than that of the gear coupling. It is small in size and light in weight. It can partially replace the gear coupling. Coupling: Compared with gear couplings, it has simple structure, fewer components, convenient manufacturing, no gear processing machine tool; convenient maintenance, longer life, and nylon pin can be replaced by removing the baffle.The nylon pin is a self-lubricating material and does not need lubrication, which not only saves lubricating oil, but also purifies the working environment.The disadvantages of elastic pin gear couplings are poor vibration reduction and high noise.Although it has the performance of compensating the relative deviation of the two shafts, it is only suitable for medium and high power transmission, and is not suitable for working parts that have certain requirements for vibration reduction and strict noise control.

The basic parameters and main dimensions of LZJ type intermediate shaft elastic pin gear coupling (GB/T 5015-2003) (unit: mm)

| model | Nominal torque Tn KN.m | Permissible speed [n] r/min | Diameter of shaft hole d1.d2 | Length of shaft hole | D | D1 | B | S | Moment of inertia kg·m2 | Weight kg |

| Y type, J1型 | ||||||||||

| L | ||||||||||

| LZJ1 | 0.112 | 4500 | 12 ~ 28 | 27 ~ 62 | 84 | 40 | 38 | 2.5 | 0.002 | 1.90 |

| LZJ2 | 0.25 | 4500 | 16 ~ 38 | 30 ~ 82 | 98 | 50 | 42 | 2.5 | 0.003 | 3.18 |

| LZJ3 | 0.63 | 4000 | 25 ~ 48 | 44 ~ 112 | 124 | 65 | 54 | 3.0 | 0.011 | 6.68 |

| LZJ4 | 1.8 | 4000 | 40 ~ 70 | 84 ~ 142 | 166 | 90 | 72 | 4 | 0.047 | 15.98 |

| LZJ5 | 4.5 | 3600 | 55 ~ 90 | 84 ~ 172 | 214 | 120 | 72 | 4 | 0.137 | 29.50 |

| LZJ6 | 8 | 3200 | 60 ~ 95 | 107 ~ 172 | 240 | 130 | 86 | 5 | 0.241 | 39.80 |

| LZJ7 | 11.2 | 2700 | 70 ~ 120 | 107 ~ 212 | 280 | 160 | 90 | 5 | 0.511 | 62.82 |

| LZJ8 | 18 | 2300 | 80 ~ 130 | 132 ~ 252 | 330 | 190 | 100 | 6 | 1.1 | 101.44 |

| LZJ9 | 25 | 2000 | 90 ~ 150 | 132 ~ 252 | 380 | 220 | 115 | 7 | 2.253 | 152.5 |

| LZJ10 | 31.5 | 1900 | 100 ~ 170 | 167 ~ 302 | 400 | 245 | 115 | 8 | 3.031 | 185.0 |

| LZJ11 | 40 | 1750 | 110 ~ 180 | 167 ~ 302 | 435 | 260 | 130 | 8 | 4.499 | 229.3 |

| LZJ12 | 63 | 1600 | 130 ~ 200 | 202 ~ 352 | 480 | 290 | 145 | 8 | 7.504 | 313.3 |

| LZJ13 | 100 | 1400 | 150 ~ 250 | 202 ~ 410 | 545 | 345 | 165 | 8 | 14.86 | 484.9 |

| LZJ14 | 125 | 1270 | 170 ~ 260 | 242 ~ 352 | 600 | 390 | 170 | 8 | 23.98 | 646.9 |

| LZJ15 | 160 | 1200 | 190 ~ 300 | 282 ~ 470 | 630 | 420 | 190 | 10 | 32.92 | 767.5 |

| LZJ16 | 250 | 1020 | 220 ~ 340 | 282 ~ 550 | 745 | 490 | 205 | 10 | 69.47 | 1210 |

| LZJ17 | 355 | 920 | 240 ~ 380 | 330 ~ 550 | 825 | 550 | 225 | 10 | 118.3 | 1635 |

| LZJ18 | 450 | 830 | 250 ~ 420 | 330 ~ 650 | 920 | 605 | 240 | 13 | 196.2 | 2168 |

| LZJ19 | 630 | 730 | 280 ~ 450 | 380 ~ 650 | 1040 | 695 | 255 | 14 | 358.1 | 3205 |

| LZJ20 | 1120 | 610 | 320 ~ 600 | 380 ~ 800 | 1240 | 800 | 285 | 15 | 766.6 | 4923 |

| LZJ21 | 1800 | 490 | 380 ~ 710 | 450 ~ 800 | 1540 | 1020 | 310 | 18 | 2143 | 9212 |

| LZJ22 | 2240 | 460 | 420 ~ 750 | 540 ~ 800 | 1640 | 1100 | 330 | 19 | 2937 | 11191 |

| LZJ23 | 2800 | 430 | 450 ~ 850 | 540 ~ 880 | 1760 | 1240 | 360 | 20 | 4477 | 14544 |

| Note: 1: Weight and moment of inertia are in Y/J1The shaft hole combination type and the calculated value of the smallest shaft hole. 2: Short-time overload shall not exceed 2 times of the nominal torque Tn | ||||||||||

- LM type basic plum blossom elastic coupling LT type (formerly TL type) elastic sleeve pin coupling LMD (formerly MLZ) type single flange plum-shaped bullet XL type star elastic coupling T type plum blossom hexagonal water pump counter wheel pad

-

Popular products

- LZJ (formerly ZLZ) type connecting intermediate shaft elastic column LZ (formerly ZL) type elastic pin gear coupling LZZ (formerly ZLL) elastic column with brake wheel LZD (formerly ZLD) type conical shaft hole elasticity

-

Related Products

-

related news