Product Description

Product Description

Chinese Manafacturer Flexible cast iron NM coupling with Rubber Element water pump Shaft coupling NM 194 214

NM type is precisely produced by a special designed synthetic rubber with 2 similar bodies of cast iron. Cast iron flanges: Designed not only for the power transmission but also for protection of flexible rubber.Flexible rubber Application: pumps, fans, coupressors, vehicles, transporting equipments, constructors, cement mixers, tractors, transmission machines, metal working machines, rollers and all other trasmissions.Made of rubber and steel corres are inserted in the teeth so as to provide excellent durability and performance of coupling.

Use:

Mainly used in the mining, metallurgical, cement, chemicals,construction, buiding materials,

electric power, telecommunictions, textiles, and transportation departments.

Such as:

1. conveyor:Belt conveyor,AFC conveyor, chain conveyor, screw conveyor.

2. Pum:Water pump, oil pump, slush pump, etc.

3.Fan: Draft fan, fanner, boil fan, etc.

4. Excator:bucket excavator bucket, wheel excavators .

5. Crane:Tower crane, gantry crande, bridge crane.

6.Others:Various elevators, coal plough, ball mill, crusher, recreation machine.

7.Blender equipment, centrifuger, washer, leather-making machine, machine for recreation

park mixer wire drawing machine.Extruder, dregs crusher of boiler.

8.Plastic feeder, rubber smelling machine, etc.

Detailed Photos

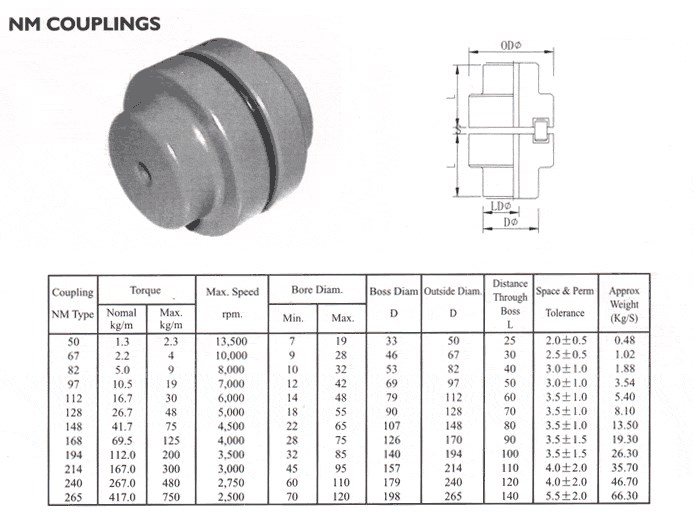

Product Parameters

| Model | Torque | Max. | Bore Diam | Boss Diam | Outsid Diam | Length | Space&Perm | Weight | ||

| Nomal | Max | Speed | Min | Max | D | OD | L | Tolerance | (kg) | |

| Kg-m | Kg-m | (RPM) | ||||||||

| NM50 | 1.3 | 2.3 | 12500 | 7 | 19 | 33 | 50 | 25 | 2.0±0.5 | 0.48 |

| NM67 | 2.2 | 4 | 10000 | 8 | 28 | 46 | 67 | 30 | 2.5±0.5 | 1.02 |

| NM82 | 5 | 9 | 8000 | 10 | 32 | 53 | 82 | 40 | 3.0±1.0 | 1.88 |

| NM97 | 10.5 | 19 | 7000 | 10 | 42 | 69 | 97 | 50 | 3.0±1.0 | 3.54 |

| NM112 | 16.7 | 30 | 6000 | 14 | 48 | 79 | 112 | 60 | 3.5±1.0 | 5.4 |

| NM128 | 26.7 | 48 | 5000 | 18 | 55 | 90 | 128 | 70 | 3.5±1.0 | 8.1 |

| NM148 | 41.7 | 75 | 4500 | 22 | 65 | 107 | 148 | 80 | 3.5±1.0 | 13.5 |

| NM168 | 69.5 | 125 | 4000 | 28 | 75 | 124 | 168 | 88 | 3.5±1.5 | 19.3 |

| NM194 | 112 | 200 | 3500 | 32 | 85 | 140 | 198 | 100 | 3.5±1.5 | 26.3 |

| NM214 | 167 | 300 | 3000 | 40 | 95 | 158 | 218 | 112 | 4.0±2.0 | 35.7 |

Certifications

Packaging & Shipping

Package: Standard suitable package / Pallet or container

Polybag inside export carton outside, blister and Tape and reel package available.

If customers have specific requirements for the packaging, we will gladly accommodate

Shipping: 10-20 working days ofter payment receipt comfirmed (based on actual quantity) Packing standard export packing or according to customers demand Professional goods shipping forwarder

Company Profile

ZheJiang Mighty Machinery Co., Ltd. specializes in manufacturing Mechanical Power Transmission Products.

We Mighty is the division/branch of SCMC Group, which is a wholly state-owned company, established in 1980.

About Mighty:

-3 manufacturing factories, we have 5 technical staff, our FTY have strong capacity for design and process design, and more than 70 workers and double shift eveyday.

-Large quality of various material purchase and stock in warhouse which ensure the low cost for the material and production in time.

-Strick quality control are apply in the whole prodution. we have incoming inspection,process inspection and final production inspection which can ensure the perfect of the goods quality.

-14 years of machining experience. Long time cooperate with the Global Buyer, make us easy to understand the csutomer and handle the export. MIGHTY’s products are mainly exported to Europe, America and the Middle East market. With the top-ranking management, professional technical support and abundant export experience, MIGHTY has established lasting and stable business partnership with many world famous companies and has got good reputation from CHINAMFG customers in international sales.

Our Advantages

1,More competitive prices,

2,Shorter delivery date: 35 days.

3,We are the professional manufacturer in the field of Power Trans.Parts,specially for Timing Pulleys.

4,Produce standard and non-standard

5,Strict QC Management:ISO9001:2008,our engineer,Mr.Wang has specialized in the prodcution for over 20 years.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory, also do trading company business. Because our company do export 36years, having our own factories, also cooperated with other many factories.

Q:What’s the MOQ?

A:We have not a clear limit,1 or 2pcs is available.

Q: How long is your delivery time?

A: 3-5 days via DHL, TNT, UPS, FEDEX.

Diffirent based on the diffirent countries of customers via CHINAMFG shipping.

Q: Do you provide samples ? is it free or extra ?

A:yes,we provide free samples for checking the build quality and real performance of our products,the freight need to be covered by customer.

Q: What is your terms of payment ?

A: T/T, Paypal, L/C, D/P, D/A, Western Union, etc., all decided by customer’s requirements.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Structure: | Flexible |

| Material: | Cast Iron |

| Type: | Flexible Coupling |

| Surface Treatment: | Phosphating |

| Name: | Nm Shaft Coupling |

| Samples: |

US$ 18.6/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can flexible couplings accommodate high torque and high-speed applications?

Yes, flexible couplings can accommodate both high torque and high-speed applications, but the suitability depends on the specific design and material of the flexible coupling. Different types of flexible couplings have varying torque and speed capacities, and it’s crucial to select the right type of coupling based on the application requirements.

High Torque Applications:

Some flexible couplings, such as gear couplings and disc couplings, are designed to handle high torque levels. Gear couplings consist of toothed hubs that mesh with each other, providing a robust and efficient torque transmission. They are commonly used in heavy-duty industrial applications, such as steel mills, mining equipment, and power generation plants, where high torque loads are prevalent.

Disc couplings are also suitable for high torque applications. They use a series of flexible metal discs that can handle significant torque while compensating for misalignment. Disc couplings are often used in high-speed machinery and critical applications where precise torque transmission is essential.

High-Speed Applications:

Flexible couplings can also be used in high-speed applications. For instance, certain disc couplings, elastomeric couplings, and grid couplings are capable of handling high rotational speeds. These couplings have low inertia, which means they can respond quickly to changes in speed and provide efficient power transmission at high RPMs.

Elastomeric couplings, such as jaw couplings and tire couplings, are commonly used in various industrial applications, including pumps, compressors, and fans, where both torque and speed requirements are high. They offer good flexibility and damping properties, making them suitable for applications with high-speed variations and vibrations.

Considerations:

When selecting a flexible coupling for high torque and high-speed applications, several factors should be considered:

- The torque and speed ratings provided by the coupling manufacturer should be checked to ensure they meet or exceed the application’s requirements.

- The design and materials of the coupling should be suitable for the specific operating conditions, including temperature, environment, and potential exposure to corrosive substances.

- Proper alignment and installation of the coupling are critical to ensure optimal performance and prevent premature wear.

- In some cases, it may be necessary to use additional components, such as torque limiters or speed reducers, to protect the coupling and the connected equipment from excessive loads or speed fluctuations.

In conclusion, flexible couplings can indeed accommodate high torque and high-speed applications, but the appropriate coupling type and proper selection are essential to ensure reliable and efficient performance in these demanding conditions.

Can flexible couplings be used in corrosive or harsh environments?

Yes, flexible couplings can be designed and selected to be used in corrosive or harsh environments. The choice of materials and coatings plays a crucial role in ensuring the coupling’s durability and performance under challenging conditions.

Corrosion-Resistant Materials:

In corrosive environments, it is essential to use materials that can withstand chemical attacks and oxidation. Stainless steel, specifically grades like 316 or 17-4 PH, is commonly chosen for flexible couplings in such situations. Stainless steel offers excellent corrosion resistance, making it suitable for applications where the coupling may come into contact with corrosive substances or moisture.

Special Coatings:

For certain harsh environments, coupling manufacturers may apply special coatings to enhance the coupling’s corrosion resistance. Examples of coatings include zinc plating, nickel plating, or epoxy coatings. These coatings provide an additional layer of protection against corrosive agents and help extend the coupling’s lifespan.

Sealed Designs:

In environments where the coupling is exposed to contaminants like dust, dirt, or moisture, sealed designs are preferred. Sealed flexible couplings prevent these substances from entering the coupling’s internal components, thus reducing the risk of corrosion and wear. The sealed design also helps to maintain the coupling’s performance over time in challenging conditions.

High-Temperature Applications:

For harsh environments with high temperatures, flexible couplings made from high-temperature resistant materials, such as certain heat-resistant stainless steels or superalloys, can be used. These materials retain their mechanical properties and corrosion resistance even at elevated temperatures.

Chemical Resistance:

For applications where the coupling might encounter chemicals or solvents, it is essential to select a coupling material that is chemically resistant. This prevents degradation and ensures the coupling’s integrity in such environments.

Specialized Designs:

In some cases, where the environment is exceptionally harsh or unique, custom-designed flexible couplings may be necessary. Engineering a coupling to meet the specific demands of the environment ensures optimal performance and reliability.

Consultation with Manufacturers:

When considering flexible couplings for corrosive or harsh environments, it is advisable to consult with coupling manufacturers or engineering experts. They can provide valuable insights and recommend suitable materials, coatings, and designs based on the specific operating conditions.

Summary:

Flexible couplings can indeed be used in corrosive or harsh environments, provided the appropriate materials, coatings, and designs are chosen. Stainless steel, sealed designs, and special coatings are some of the solutions that enhance the coupling’s corrosion resistance and performance. It is essential to consider the specific environment and application requirements when selecting a flexible coupling to ensure optimal functionality and durability in challenging conditions.

Can flexible couplings handle misalignment between shafts?

Yes, flexible couplings are specifically designed to handle misalignment between shafts in rotating machinery and mechanical systems. Misalignment can occur due to various factors, including installation errors, thermal expansion, manufacturing tolerances, or shaft deflection during operation.

Flexible couplings offer the ability to compensate for different types of misalignment, including:

- Angular Misalignment: When the shafts are not collinear and have an angular offset, flexible couplings can accommodate this misalignment by flexing or twisting, allowing the two shafts to remain connected while transmitting torque smoothly.

- Parallel Misalignment: Parallel misalignment occurs when the two shafts are not perfectly aligned along their axes. Flexible couplings can adjust to this misalignment, ensuring that the shafts remain connected and capable of transmitting power efficiently.

- Axial Misalignment: Axial misalignment, also known as end float or axial displacement, refers to the relative axial movement of the two shafts. Some flexible coupling designs can accommodate axial misalignment, allowing for slight axial movements without disengaging the coupling.

The ability of flexible couplings to handle misalignment is essential in preventing premature wear and failure of the connected equipment. By compensating for misalignment, flexible couplings reduce the stress on the shafts, bearings, and seals, extending the service life of these components and improving overall system reliability.

It is crucial to select the appropriate type of flexible coupling based on the specific misalignment requirements of the application. Different coupling designs offer varying degrees of misalignment compensation, and the choice depends on factors such as the magnitude and type of misalignment, the torque requirements, and the operating environment.

In summary, flexible couplings play a vital role in handling misalignment between shafts, ensuring efficient power transmission and protecting mechanical systems from the adverse effects of misalignment. Their ability to accommodate misalignment makes them indispensable components in various industrial, automotive, aerospace, and marine applications.

editor by CX 2024-04-16