-

Star flexible coupling

-

Plum-shaped elastic coupling

-

Slider coupling

-

Diaphragm coupling

-

Elastic sleeve pin coupling

-

Elastic pin coupling

-

Elastic pin gear coupling

-

Drum gear coupling

-

Rigid coupling

-

Tyre coupling

-

Universal coupling

-

Water pump coupling

-

Roller chain coupling

-

Reducer bracket

-

Blender

-

Stuffing box

-

Expansion sleeve

-

Various coupling accessories

-

Product Navigation

- LM type basic plum blossom elastic coupling

- LT type (formerly TL type) elastic sleeve pin coupling

- LMD (formerly MLZ) type single flange plum-shaped bullet

- XL type star elastic coupling

- Ever-Power Factory Slider Coupling

- Ever-Power explains the elastic pin teeth for you

- Operation and structure of star coupling

- The editor will introduce you to each model

- The coupling is divided into lubricated and non-lubricated

- What to consider when buying a coupling

-

更新 更新

-

Product display Coupling > Product center > Tyre coupling >

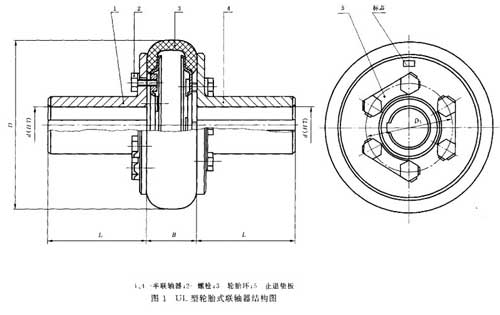

UL tire coupling detailed parameters

The UL type tire coupling is vulcanized and bonded together with a rubber element (tire body) and a metal pressure plate, and the two halves of the coupling are directly connected with bolts during assembly.The working temperature is -20~80℃, and the nominal torque is 10-25000N.m.

Features of tire coupling:

1. Simple structure, no lubrication, easy disassembly and maintenance, no need to move the coupling axially when changing the tire body.

2. It has high elasticity, low torsional stiffness, strong vibration damping ability, and great ability to compensate the relative displacement of the two shafts.

3. It has good damping and low noise, but the load-bearing capacity is not high, the radial dimension is large, and a large axial additional load is generated when overloaded.

4. It is suitable for two-axis connection with frequent starting, changeable forward and reverse rotation, and large shock and vibration. It can work under dust and moisture conditions.

UL tire coupling is a kind of highly elastic coupling. In addition to its excellent cushioning and shock absorption performance, it has excellent compensation performance for axial, radial and angular deviations, which can effectively reduce the equipment during operation. The current peak value is reduced by 50% compared with other couplings.Through the special rubber process design, in addition to no lubrication and maintenance-free, it is especially suitable for humid and dusty working environments.

The standard half-coupling structure is type K, which can no longer be marked in the display.

The rubber element (tire body) and the metal pressure plate are vulcanized and bonded together, and the two halves of the coupling are directly connected with bolts during assembly

Flexible, large damping, large compensation

Simple structure, easy assembly, no need to move the coupling axially when changing the tire body

Basic parameters and main dimensions of UL type tire coupling (GB/T 5844-2002) (unit: mm)

| model |

Nominal torque Tn (Nm) |

Momentary maximum torque Tmax(Nm) |

Permissible speed r / min |

Diameter of shaft hole d |

Length of shaft hole L |

D | B |

Moment of inertia (kg.m2) |

Weight (kg.m³) | ||

| steel | iron | steel | iron | ||||||||

| UL1 | 10 | 31.5 | 5000 | 3500 | 11-18 | 11-16 | 22-42 | 80 | 20 | 0.0003 | 0.7 |

| UL2 | 25 | 80 | 5000 | 3000 | 14-22 | 14-20 | 32-52 | 100 | 26 | 0.0008 | 1.2 |

| UL3 | 63 | 180 | 4800 | 3000 | 18-25 | 18-22 | 30-62 | 120 | 32 | 0.0022 | 1.8 |

| UL4 | 100 | 315 | 4500 | 3000 | 20-30 | 20-25 | 38-82 | 140 | 38 | 0.0044 | 3 |

| UL5 | 160 | 500 | 4000 | 3000 | 24-35 | 24-30 | 38-82 | 160 | 45 | 0.0084 | 4.6 |

| UL6 | 250 | 710 | 3600 | 2500 | 28-40 | 28-35 | 44-112 | 180 | 50 | 0.0146 | 7 |

| UL7 | 315 | 900 | 3200 | 2500 | 32-48 | 32-42 | 60-112 | 200 | 56 | 0.029 | 10.9 |

| UL8 | 400 | 1250 | 3000 | 2000 | 38-50 | 38-45 | 60-112 | 220 | 63 | 0.0448 | 13 |

| UL9 | 630 | 1800 | 2800 | 2000 | 42-60 | 42-55 | 84-142 | 250 | 71 | 0.0898 | 20 |

| UL10 | 800 | 2240 | 2400 | 1600 | 45-70 | 45-65 | 84-142 | 280 | 80 | 0.1596 | 30.6 |

| UL11 | 1000 | 2500 | 2100 | 1600 | 50-75 | 50-65 | 84-142 | 320 | 90 | 0.2792 | 39 |

| UL12 | 1600 | 4000 | 2000 | 1600 | 55-85 | 55-80 | 84-172 | 360 | 100 | 0.5356 | 59 |

| UL13 | 2500 | 6300 | 1800 | 1600 | 63-95 | 63-95 | 104-172 | 400 | 110 | 0.896 | 81 |

| UL14 | 4000 | 10000 | 1600 | 1400 | 75-110 | 75-110 | 107-212 | 480 | 130 | 2.2616 | 142 |

| UL15 | 6300 | 14000 | 1200 | 1120 | 85-125 | 90-125 | 132-212 | 560 | 150 | 4.6456 | 222 |

| UL16 | 10000 | 20000 | 1000 | 1000 | 100-140 | 100-140 | 167-252 | 630 | 180 | 8.0924 | 302 |

| UL17 | 61000 | 31500 | 900 | 850 | 120-160 | 130-160 | 167-302 | 750 | 210 | 20.0176 | 561 |

| UL18 | 25000 | 50000 | 800 | 750 | 140-180 | 150-170 | 202-302 | 900 | 250 | 34.053 | 818 |

You may be right | Tyre coupling | LLB type tire coupling | Interested in other products

- LM type basic plum blossom elastic coupling LT type (formerly TL type) elastic sleeve pin coupling LMD (formerly MLZ) type single flange plum-shaped bullet XL type star elastic coupling T type plum blossom hexagonal water pump counter wheel pad

-

Popular products

- UL tire coupling LLB type framed tire coupling DL polygonal rubber coupling LLA type non-framework tire coupling LAK type saddle block elastic coupling

-

Related Products

-

related news