-

Star flexible coupling

-

Plum-shaped elastic coupling

-

Slider coupling

-

Diaphragm coupling

-

Elastic sleeve pin coupling

-

Elastic pin coupling

-

Elastic pin gear coupling

-

Drum gear coupling

-

Rigid coupling

-

Tyre coupling

-

Universal coupling

-

Water pump coupling

-

Roller chain coupling

-

Reducer bracket

-

Blender

-

Stuffing box

-

Expansion sleeve

-

Various coupling accessories

-

Product Navigation

- LM type basic plum blossom elastic coupling

- LT type (formerly TL type) elastic sleeve pin coupling

- LMD (formerly MLZ) type single flange plum-shaped bullet

- XL type star elastic coupling

- Ever-Power Factory Slider Coupling

- Ever-Power explains the elastic pin teeth for you

- Operation and structure of star coupling

- The editor will introduce you to each model

- The coupling is divided into lubricated and non-lubricated

- What to consider when buying a coupling

-

更新 更新

-

Product display Coupling > Product center > Tyre coupling >

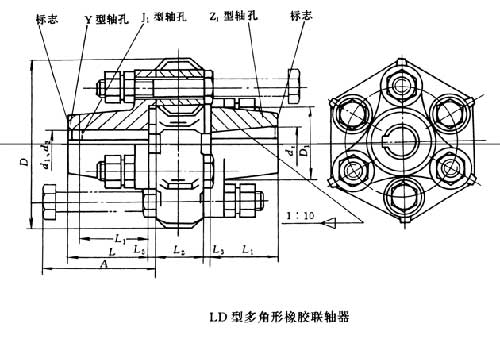

DL Polygonal Rubber Coupling is made of rubber material, made into a 6-corner (or octagonal) elastic piece with a circular cross-section, and a sleeve bonded with rubber after vulcanization is embedded in each position. The 8 (or 6) bolts passing through the casing are alternately connected with the half coupling flanges on the main and driven ends. The polygonal rubber coupling has a simple structure, does not require lubrication, is easy to assemble and disassemble, and has a gentle transmission. The torsional vibration and impact load of the shafting can prevent resonance of the transmission shafting and can compensate for the relative deviation of the two axes.

The basic parameters and main dimensions of LD polygonal rubber coupling (JB/T 5512-1991) (unit: mm)

| model | Nominal torque Tn/Nm | Allowable speed [n]/r/min | Allowable torsion angle/(°) | Axle hole diameter d1, d2, dz | Length of shaft hole | D | D1 | L2 | L3 | A | Moment of inertia kg.m2 | Mass kg | |

| Y type | J1, Z1 type | ||||||||||||

| L | L1 | ||||||||||||

| LD1 | 50 | 5000 | 5 | 12, 14 | 32 | - | 96 | 42 | 75 | 28 | 75 | 0.001 | 1.9 |

| 16, 18, 19 | 42 | 30 | |||||||||||

| 20, 22, 24 | 52 | 38 | |||||||||||

| 25 | 62 | 44 | |||||||||||

| LD2 | 80 | 4000 | 16, 18, 19 | 42 | 30 | 118 | 55 | 85 | 32 | 85 | 0.0031 | 3.9 | |

| 20, 22, 24 | 52 | 38 | |||||||||||

| 25, 28 | 62 | 44 | |||||||||||

| 30, 32 | 82 | 60 | |||||||||||

| LD3 | 160 | 3150 | 4 | 20, 22, 24 | 52 | 38 | 142 | 68 | 105 | 46 | 105 | 0.0089 | 8 |

| 25, 28 | 62 | 44 | |||||||||||

| 30-32-35 | 82 | 60 | |||||||||||

| 40 | 112 | 84 | |||||||||||

| LD4 | 280 | 2500 | 22, 24 | 52 | 38 | 182 | 92 | 120 | 52 | 120 | 0.026 | 14.2 | |

| 25, 28 | 62 | 44 | |||||||||||

| 30-32-35 | 82 | 60 | |||||||||||

| 40, 42, 45, 48, 50, 55 | 112 | 84 | |||||||||||

| LD5 | 560 | 2000 | 25, 28 | 62 | 44 | 235 | 122 | 140 | 62 | 140 | 0.095 | 31.4 | |

| 30-32-35 | 82 | 60 | |||||||||||

| 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | |||||||||||

| 60, 63, 65, 70, 71 | 142 | 107 | |||||||||||

| LD6 | 800 | 1800 | 28 | 62 | 44 | 258 | 128 | 150 | 68 | 150 | 0.132 | 35.6 | |

| 30-32-35 | 82 | 60 | |||||||||||

| 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | |||||||||||

| 60, 63, 65, 70, 71 | 142 | 107 | |||||||||||

| LD7 | 1250 | 1600 | 35, 38 | 82 | 60 | 282 | 148 | 185 | 78 | 185 | 0.287 | 58.4 | |

| 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | |||||||||||

| 60, 63, 65, 70, 71, 75 | 142 | 107 | |||||||||||

| 80, 85 | 172 | 132 | |||||||||||

| LD8 | 2500 | 1250 | 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | 372 | 190 | 230 | 100 | 230 | 0.952 | 117.1 | |

| 60, 63, 65, 70, 71, 75 | 142 | 107 | |||||||||||

| 80-85-90 | 172 | 132 | |||||||||||

| 100, 110 | 212 | 167 | |||||||||||

| LD9 | 3550 | 1120 | 45, 48, 50, 55, 56 | 112 | 84 | 420 | 220 | 270 | 115 | 270 | 1.981 | 171.8 | |

| 60, 63, 65, 70, 71, 75 | 142 | 107 | |||||||||||

| 80-85-90 | 172 | 132 | |||||||||||

| 100, 110, 120, 125, 130 | 212 | 167 | |||||||||||

| LD10 | 5600 | 1000 | 50, 55, 56 | 112 | 84 | 465 | 242 | 295 | 130 | 295 | 3.606 | 252.9 | |

| 60, 63, 65, 70, 71, 75 | 142 | 107 | |||||||||||

| 80-85-90 | 172 | 132 | |||||||||||

| 100-110-120 | 212 | 167 | |||||||||||

| 130, 140, 150 | 252 | 202 | |||||||||||

| LD11 | 8000 | 900 | 60, 63, 65, 70, 71, 75 | 142 | 107 | 520 | 260 | 365 | 150 | 365 | 7.48 | 386.7 | |

| 80-85-90 | 172 | 132 | |||||||||||

| 100-110-120 | 212 | 167 | |||||||||||

| 130, 140, 150 | 252 | 202 | |||||||||||

| 160 | 302 | 242 | |||||||||||

- LM type basic plum blossom elastic coupling LT type (formerly TL type) elastic sleeve pin coupling LMD (formerly MLZ) type single flange plum-shaped bullet XL type star elastic coupling T type plum blossom hexagonal water pump counter wheel pad

-

Popular products

- UL tire coupling LLB type framed tire coupling LAK type saddle block elastic coupling DL polygonal rubber coupling LLA type non-framework tire coupling

-

Related Products

-

related news